In stage technology, on oil platforms or in process cranes – the rollable e-spool is used wherever cables have to be moved safely and in the tightest of spaces.

The compact igus energy chain system, available from Treotham Automation, is an alternative to the classic cable drum. It has two major differences: the e-spool is the only solution that can carry not only energy, but also all media such as data, compressed air and liquids. That’s because it connects two different energy supply systems in one.

A standard e-chain, which is guided by a guide roller, always ensures with an integrated retaining spring the correct length and tension of the e-chain system. An igus twisterband is responsible for the rotational movements.

This special structure makes movements in every direction possible.

Another difference: the e-spool does not need an expensive slip ring. This means the most diverse cables can be continuously connected in a confined space in a system, and also be replaced or added at any time.

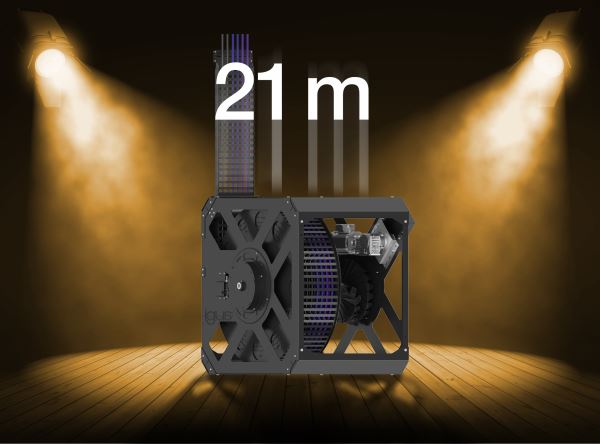

To help users to fall back on the practical energy chain solution for longer travels, igus has developed a new e-spool standard for 21m.

Optimised structure for more filling and carrying capacity

The new e-spool has evolved from customer requirements and experience of recent years and covers the gap between the spring-driven standard e-spool for up to 14m extension length and the motorised e-spool for large projects, for example in the offshore sector or in opera houses.

The new energy chain system was equipped with a larger twisterband for a higher filling. To compensate for the payload and extension length, the new structure of the e-spool provides more bracing, a more stable all-enclosing body and a reinforced floor plate as a retraction safeguard.

To withstand the higher forces, the developers also opted for an optimised mechanism for adjusting the spring force. The new e-spool standard is available either as a spring-driven version with 2 HD springs or as a motor-driven version with a built-in stationary motor.

Treotham Automation Pty Ltd

1300 65 75 64