The automation of production processes is becoming increasingly important for mechanical engineering to manufacture products within the shortest possible time and at low cost.

The key to success is being able to move with ease and precision in the smallest of spaces.

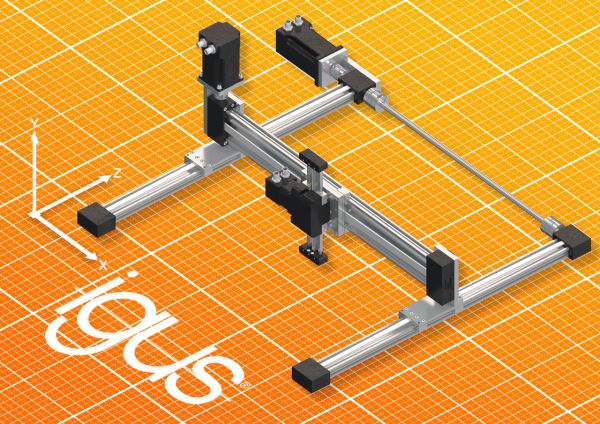

For this reason, igus has developed the new, compact linear robot.

The new lubrication-free and maintenance-free drylin E linear robot is suitable for a wide range of applications, be it in medical technology with high safety requirements, or tasks in microelectronics, or for pick and place functions for very small series.

In a small working envelope of 400 x 400 x 100mm, the small, complete solution can carry loads of up to 2.5kg at maximum speeds of up to 0.5m per second.

Two drylin ZLW toothed belt axes and one drylin GRW gear rack axis ensure precise guidance and lubrication-free operation thanks to sliding elements made of high-performance plastics.

Mounting brackets for system profiles are also available as an option. The linear robot, available in Australia from Treotham Automation, is delivered ready to connect with NEMA17/23 stepper motors and encoders.

Treotham Automation Pty Ltd

1300 65 75 64