Grips easily, cost-effectively and quickly – that’s what the new delta robot from Treotham does.

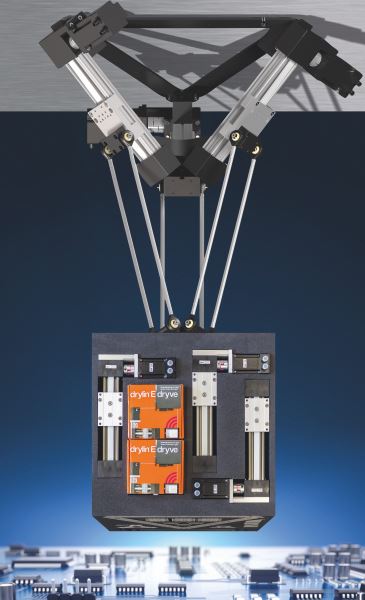

Comprising maintenance-free toothed belt axes, lubrication-free links, encoders and stepper motors, igus has developed this easy automation solution for assembly tasks.

With this delta robot you can automate simple tasks quickly, easily and cost-effectively.

The robot is based on three maintenance-free drylin ZLW toothed belt axes, lubrication-free igubal coupling bars and matching adapter plates.

NEMA stepper motors and encoders ensure the quick handling of up to 1kg with a precision of ± 0.5mm.

The complete system has an installation space of up to 420 mm in diameter and can carry up to 5kg at low speeds. The lightweight construction with aluminium and plastic makes the delta robot extremely cost-effective and provides high speeds with a pick rate of at least 60 per minute.

Easy to install

Depending onequirements, the new delta robot can be delivered as a pre-assembled construction kit with assembly instructions, or as a ready-to-install system in a transport frame.

As an option, you can use your own software and control system, or the intuitive and easy-to-use dryve D1 control system.

This robot is ideal for simple assembly functions, pick and place tasks, as well as applications in inspection technology.

Treotham Automation also offers other low-cost robotics systems with the igus robolink product range.

Users can assemble robot arms with up to five axes from a modular system consisting of different joints with a wide variety of plastic gears, motors and interface connectors.

Treotham Automation Pty Ltd

1300 65 75 64