Through automation technology and robotics industrial businesses enable their employees to dedicate time to more intellectually demanding projects.

At the same time, they can improve quality, reduce risk of injury associated with dangerous tasks and lower overall operational costs.

According to the NASDAQ Artificial Intelligence & Robotics report, industrial businesses spent US$11 billion on robots installed across the globe in 2015.

This year, the International Federation of Robotics (IFR) says global sales will hit a record US$16.5 billion.

More than 2.4 million industrial robots are currently operating in global factories. Between 2020 and 2022, in the Industry 4.0 era, another almost two million new industrial robots will be installed.

According to Thomasnet.com, a leading US industrial sourcing platform, sourcing has increased for automation equipment by 137.8 percent year-over-year (YOY), for manufacturing automation equipment by 184.6 percent YOY and for automation engineering services by a massive 284.7 percent YOY.

Also, sourcing for robots has jumped 91.4 percent YOY, with sourcing for robotics growing similarly, yet more cautiously, at 6.5 percent YOY.

“Since their initial installation into industrial settings, robots’ capabilities have increased tremendously,” says Thomas CEO Tony Uphoff.

More user-friendly and intuitive

This has empowered manufacturers to implement the technology across varying industrial sectors and production phases.

“Now more user-friendly and intuitive, manufacturers can independently install and update their robots and automation technology more easily than years ago,” Uphoff says.

“As labour becomes increasingly expensive, the skills gap grows, and the cost of robots drops, automation technology also presents industrial business leaders with alternative labour options.

“Robots are unwaveringly willing to conduct tasks otherwise dangerous to a human worker, and they can complete monotonous tasks more quickly and consistently than their human counterparts.”

That doesn’t mean robots will be completely replacing human employees, he adds.

Smaller markets recognising the benefits

“There are currently only 99 robots per 10,000 employees in the manufacturing industry, according to the IFR.

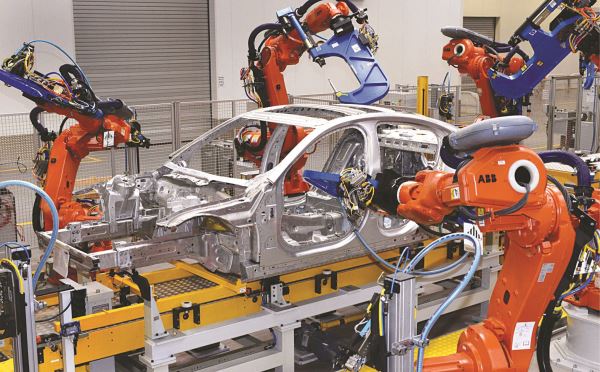

“While many smaller markets are quickly recognising the benefits and beginning to incorporate such technologies into their operations, major growth in these sectors worldwide has been primarily fuelled by the automotive market.

“As automotive production becomes increasingly complex, competitive, and individualized, the utilization of automation and robots in its production processes will continue.”

In the US, the automotive sector was responsible for 30 percent of all robot installations in 2018.

And while only 8 percent of US companies have already implemented robotic systems, 24 percent say they plan to incorporate autonomous robots and assistance systems within the next 2-5 years. A further 20 percent plan to do so within the next 12-24 months.

“We anticipate a slowdown in sourcing for these sectors in the foreseeable future driven by the uncertainty of ongoing US-China trade tensions and the upcoming US elections but expect continued investments in the long run,”