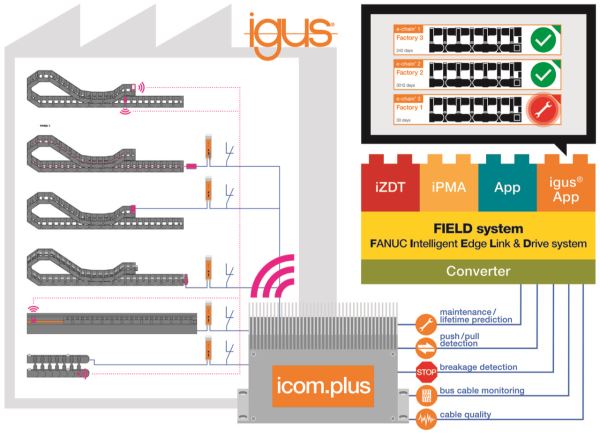

Motion plastics specialist igus has developed a smart plastics app for robotics company FANUC so it can monitor the condition of its igus components, such as energy chains and cables, allowing all maintenance work to be planned in good time.

The app is to be used in conjunction FANUC’s new IoT platform, FANUC Intelligent Edge Link & Drive system (FIELD), which enables data to be evaluated from and systems centrally.

The system can connect production machines of all manufacturers by means of a local network topology, enabling comprehensive data analysis of the entire process chain.

With the FIELD system, production machines can be networked with each other. It can work "on premise" or, in future, with a cloud link.

The system collects and analyses the machine data on site. Therefore, machine operating data and sensor data can be gathered centrally via one server and viewed whenever necessary. Efficiency is easy to monitor; production processes can be accelerated and maintenance work can be planned.

Due to the openness of the platform, all machines can be connected to the system. Apps for the system are provided by FANUC as well as by third-party suppliers. igus has developed an app for its smart plastics and made it available to the FIELD platform.

Once the igus smart plastics app has been integrated, users can monitor the condition of their energy chains and cables at any time and can also plan maintenance work well in advance. In the future, the condition of slewing rings, linear and plain bearings will also be monitored with the app.

Connection via icom.plus in a secure environment

Under the name isense, igus carries sensors of various kinds that detect the condition of igus components. The sensors measure, among other things, the wear during operation and alert the user early enough to plan repair or replacement.

The icom.plus communication module provides the igus data via an integrated OPC-UA server. This data is then fed into the platform by means of the FANUC converter.

"Due to the openness of the FIELD system, the customer can now use the data and service life statements of all igus products in a protected local network environment,” said igus’ Head of the smart plastics Business Unit, Richard Habering.

"The igus smart plastics app tells the maintenance technician when they should carry out the next maintenance. Unscheduled machine downtime can be avoided."

The FIELD system apps, like the igus smart plastics app, can be downloaded by the user from the FIELD system app store. Here, customers can choose their desired software solutions themselves.

For more information contact Treotham Automation.

Treotham Automation Pty Ltd

1300 65 75 64

www.treotham.com.au