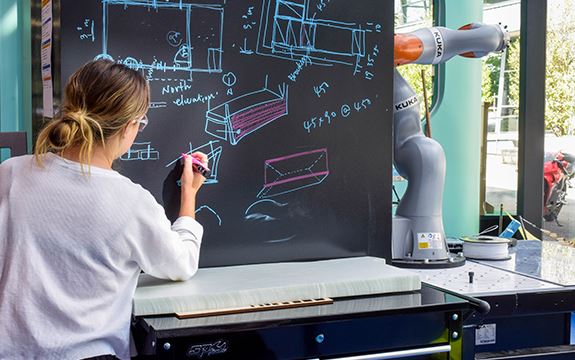

Students at Swinburne University in Melbourne are now gaining hands on experience with the latest robotics and automation technology following the opening of a new digital fabrication facility.

The state-of-the-art ProtoLAB has been designed by H2O Architects and houses industrial robots for large scale architectural design prototyping.

The design features a glass façade, allowing natural light into all corners of the workspace.

Prototyping, digital fabrication, design and making in progress can easily be observed at the new facility located at the northern end of Swinburne’s Hawthorn campus.

“Often people will be staring in, checking out what our fantastic students are creating,” says Manager of Technical Services, Architecture and Design, Andrew Tarlinton.

“Children press their faces against the glass, mesmerised, watching something being machined out of a block of foam – as if to appear by magic.”

The lab has a new high-speed HP Jet Fusion 3D Printer that allows students to print complex geometry without needing to remove support material.

It also equipped with:

- A new Okuma CNC turn mill

- Seven laser cutters

- A Biesse CNC router

- A Multicam router

- Two KUKA collaborative robots designed to work with humans and

- A new larger KUKA KR120 robot

“The KUKA KR120 runs on a 7.9 metre linear track and reaches out to 3 metres. It has a sync table at one end and a horizontal positioner along one side for multi-axis machining,” says Tarlinton.

“Computer programs, and the students tethered to them are getting smarter, utilising parametric software to control not only a model’s shape but also the robot or machine attached.

“By using data and analytics they work out what’s required, reducing waste material and improving user experience. Generative design and parametric design are not new ways of working, but we are progressively finding easier ways of producing designs and communicating to the machines.”

Deeper technical knowledge and understanding

Tarlinton says by teaching the full potential of Industry 4.0 machines, students can translate the capabilities back into their designs with a deeper technical knowledge and understanding.

The ProtoLAB supports students in design, engineering and architecture and meets the needs of academic research, testing and industry partnered work.

“In research, it supports conversations with research partners,” says Dean of Design, Professor Jane Burry.

“We also now have the space and large-scale robotics to undertake prototyping, fabrication and assembly at architectural scale.”

A “soft prototyping lab” integrates with design studios. As ideas developed in the studios mature and upscale, they are translated to the main workshop space to use the large-scale robot to fabricate at full scale, embracing the added risks and complexities that entails.

“The ProtoLAB provides the luxury of space. Multiple classes and research activities occur simultaneously. Time consuming fabrication activities continue alongside student teaching,” says Professor Burry.

“In design, access to a top-quality workshop is a major attractor for both students and researchers for testing and developing ideas,” she says.

“The quality of the workshop and expertise of staff is critical, and regular access invaluable.”