The building projects taken on by Aectual, are unique, modern and functional.

The Dutch company manufactures customised floor coverings, walls and stairs, to create a special experience. Aectual can implement the most complex requirements of designers, project developers, builders and architects.

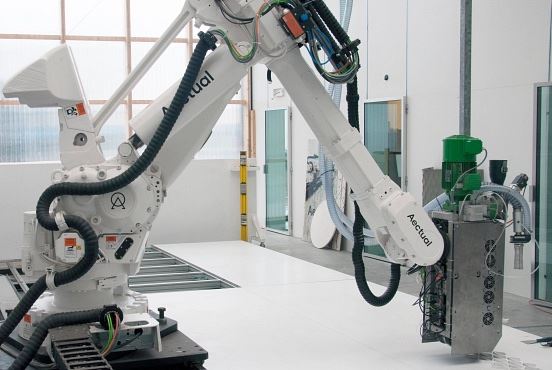

Their work can be found in Amsterdam’s Schiphol airport – the terminal’s 2,000 sqm of flooring features an integrated floor marking system. The facades and interior elements are manufactured with an XXL robotic printer.

It is one of the largest of its kind in Europe and the only printer that can run in “lights out” mode (that is, remotely without server access). It features printing speeds of up to half a metre per second. Aectual’s extrusion technology is integrated directly into the robot.

Granulate consisting of organic-based or recycled material is melted in the extruder, and a worm gear moves it directly to the printing nozzle. The extruder uses a number of different sensors and driven components. Laying power cables and analogue and digital signal cables proved to be a challenge.

The many cables should be laid as compactly and robustly as possible to maintain lights out operation. igus, the motion plastics specialist, provides the right cable protection system in the form of its energy chains.

Reliable cable guidance on the robot

“The chainflex robot cables enabled us to make our system cleaner, more efficient and more reliable,” says Hedwig Heinsman, Aectual’s Co-founder and Chief Commercial Officer.

“Because all cables have the same connectors, they are easy to replace during maintenance. Easy cable replacement will also enable us to equip our extruders with other digital fabrication tools in the future.”

All cables are guided reliably in a triflex R energy chain designed specifically for three-dimensional applications in robots. It ensures that no cable twists or fails.

For cable retraction at the robot head, Aectual used a pneumatic retraction system (RSP).

“This allows us to ensure that the cables and hoses are guided safely, even with large arm diameters and very complex movements”, says Jörg Ottersbach, Head of igus GmbH’s e-chain Business Unit.

“A pneumatic cylinder on the individual application makes retraction forces infinitely adjustable.”

And Aectual uses igus motion plastics products not only in the six robot axes, but also for supplying the robot via the seventh axis, where the developers use an E4/light energy chain to ensure safe cable movement.

The chain is remarkable for its low weight, competitive price and large interior.

All of the igus products are available from Treotham Automation.

Treotham Automation Pty Ltd

1300 65 75 64