CSIRO's Data61, the data and digital specialist arm of Australia's national science agency, has launched a new Mixed Reality Lab in Melbourne.

The lab will enable manufacturing and other industries to create “digital twins”, or virtual replicas of physical objects and systems.

By 2020, the International Data Corporation (IDC) estimates 30 per cent of the top 2000 global companies will be using data from Digital Twins of Internet of Things (IoT) connected assets to improve product innovation success rates and organisational productivity, achieving gains of up to 25 per cent.

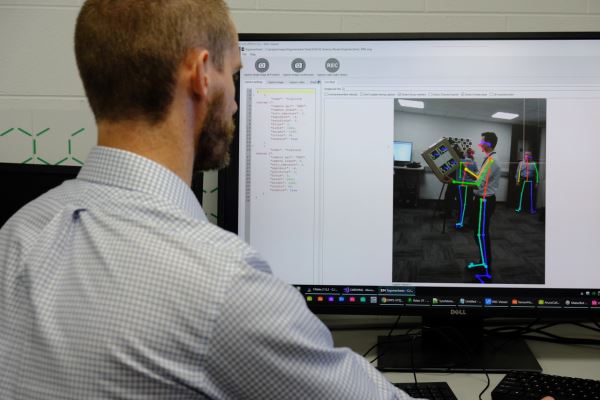

The Mixed Reality Lab houses a set-up of industrial and consumer optical cameras and sensing equipment to capture detailed information about a physical object and the space surrounding it.

The equipment is underpinned by sophisticated algorithms which merge the enormous amounts of data collected to create a digital twin in a matter of minutes.

Game-changing technology for industry

Matt Bolger, senior software engineer at CSIRO's Data61, said the lab is a unique combination of Data61's research expertise across machine learning, computer vision, computational modelling, IoT, and CSIRO's patented Stereo Depth Fusion technology for depth estimation.

"This technology is game-changing for manufacturing and other industries.

"By comparing a digital twin of a manufactured object against the original design, we can quickly, accurately and cost-effectively identify defects and map entire manufacturing processes across a global supply chain.

"Defective components can be identified in real-time and corrected, while downstream processes can be adjusted to minimise the impact of delays," Mr Bolger said.

Dr Simon Barry, Analytics and Decision Sciences research director at CSIRO's Data61 said the Mixed Reality Lab is an example of the Fourth Industrial Revolution in action, the blurring of the lines between the physical, digital and biological spheres.

Better decision making and planning

"This is the future of smart factories, where the digitalisation of the full value chain will enable real-time situational awareness and lead to better decision making and planning," Dr Barry said.

"Digital twins of manufacturing processes, human movement and even our cities and infrastructure will significantly improve productivity, reduce costs and transform all manner of industries," he said.

Minister for Industry, Science and Technology Karen Andrews said the Mixed Reality Lab is a prime example of how technology can create new value in a vital sector of the economy.

"Taking up technologies, like digital twins and augmented reality, can improve productivity and strengthen our competitive advantage in a global value chain,” she said.

"A thriving manufacturing sector is part of our government's plan to grow the economy and create 1.25 million new jobs over the next five years.”

Analysing human movement

The Mixed Reality Lab can be scaled depending on the size of the object being scanned.

It can be tailored to applications across health, agriculture, mining and other industries to automatically validate a component or process.

"Our technology can also be applied to humans to analyse their movement, using deep learning and biomechanical modelling," Mr Bolger said.

"This could help elite athletes improve their performance and reduce workplace injuries."

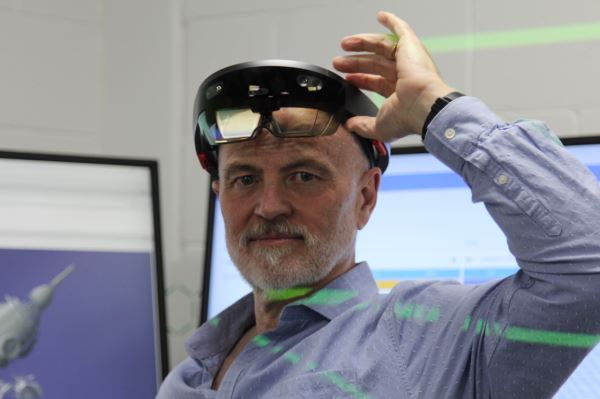

Researchers are exploring the use of augmented reality technology to allow, for example, workers on a factory floor to spot a defective object and identify where it deviates from specifications.

The Mixed Reality Lab is underpinned by Workspace, a powerful scientific application development platform, created by CSIRO's Data61.

Visit Mixed Reality Lab for more information.