A program aimed at inspiring the next generation of micro engineers is beginning to pay off for an advanced manufacturing hub in Adelaide.

The South Australian node of the Australian National Fabrication Facility (ANFF-SA) is one of eight university-based hubs around Australia, which are funded by Commonwealth and State Governments, the CSIRO and participant universities.

Complementing the University of South Australia’s Future Industries Institute’s research infrastructure at its Mawson Lakes campus, ANFF-SA started out a decade ago specialising in microfluidics. While this remains a key strength, ANFF-SA’s expertise has grown to include lab-on-a-chip technology, advanced sensing, functional coatings and separation science.

The node has more than $12 million worth of state-of-the-art equipment including a high-tech micro-milling machine, micro-injection moulder, 3D micro X-ray imaging together with a deep reactive ion etcher and advanced lithographic equipment housed within ISO Class 5 & 6 clean rooms.

As part of its growth strategy ANFF-SA has run a week-long Winter School for the state’s most promising micro-engineering graduates since 2014 and more than 250 students have gone through the Mawson Lakes program.

While predominantly filled with South Australians, the 50 places at the school are also filled with participants from interstate and overseas each year.

Engaging the right students

Past Winter School students are now using the facility for their own research or encouraging their own students to complete the four-day July course.

Node Director Associate Professor Craig Priest said the Winter School model ensures the next generation of micro engineers enter the workforce knowing about ANFF’s capabilities and potential value as an industry resource.

He said the node had been strategic about employing expert technicians and engaging the right students.

“We have world-class equipment so it’s our technicians, service and the partnerships that we’ve built with people around the world that has set us apart,” Associate Prof Priest said.

“The Winter School is one of those initiatives that doesn’t return an investment immediately but we’re now at the five-year stage so I think we’re starting to see more of it.

“These graduates have now gone out and got jobs – there’s about 250 of them and they know we are here and ready to help them, they know the technologies we’ve got and hopefully we can solve some problems for them.”

ANFF-SA Node Director Craig Priest

ANFF-SA Node Director Craig Priest

The node has three basic models of interacting with researchers and industry:

-

Working with researchers to design and make a device that supports their research towards commercialisation;

-

Industry needing a specialised component or device designed and manufactured for them using the node’s expertise and equipment;

-

Industry sending staff directly to ANFF or asking the node to recruit a specialist to work on their project within the facility.

Products developed in recent years include a microfluidic device offering gene-modified cell therapy, a non-invasive device to test urine for the presence of bladder cancer cells, a micro needle for an in-home blood-testing platform and a microfluidic chip for high-value mineral extraction.

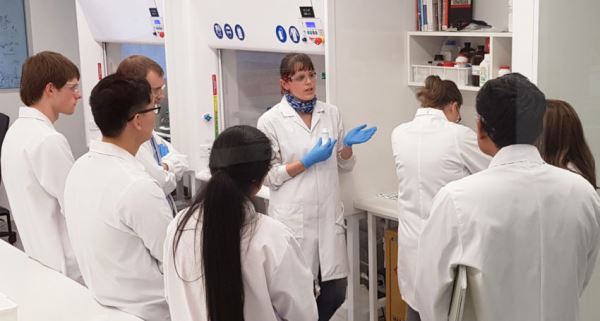

Winter School students are a mix of graduates, Honours and PhD students and researchers taking part in an interactive program on the design and fabrication of microfluidic/electronic, micro-electro-mechanical systems, optical and sensing chips.

“We are strengthening the knowledge base of our up-and-coming engineers as Winter School exposes them to emerging techniques using our cutting-edge technologies. They can incorporate these innovations into their learnings as they pursue careers in the new economy,” Associate Prof Priest said.

Achieving better outcomes for industry

“So we need to get as many people aware of this capability in industry and academia so that when that undergraduate goes out, gets a job and finds a problem they know that we’re here.

“We’re experiencing success. More work will support further growth of ANFF-SA meaning we can achieve better outcomes for industry and we’ll be able to truly transform the economy.”

Nanotechnology researcher at Curtin University in Western Australia Deepali Arora participated in the inaugural ANFF-SA Winter School in 2014 and returned this year to help run a Winter School practical session and use the clean room for one of her own projects.

Arora said the course provided hands-on experience, excellent networking and opportunities to ask complex questions of technical experts.

Work experience

“The ANFF-SA Winter School was a fantastic opportunity to meet, interact and observe some of the finest professionals across a vast networking of fields, both industrial and academic, as they demonstrate how they effectively utilize micro-fabrication to achieve their goals,” she said.

ANFF-SA has a partnership with Brighton Secondary School in Adelaide to mentor students participating in the global Formula 1 in Schools program where schools design, build and race their own scale model F1 car.

The node also offers work experience to high school students who demonstrate a passion for science.

National Facility Manager Simon Doe wants to hear from micro engineers interested in next year’s Winter School.

Andrew Spence is a senior writer with The Lead, South Australia

Researcher Claudia Binder takes Winter School students through a practical session