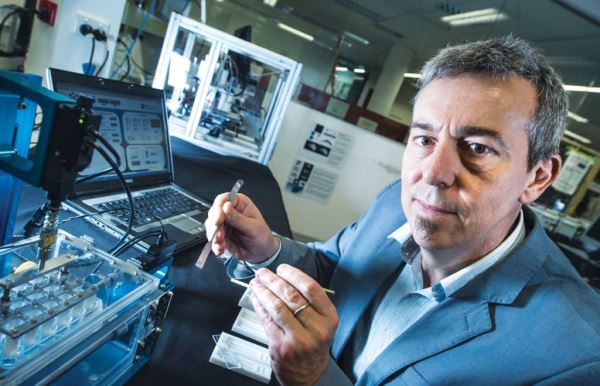

Distinguished Professor Dietmar W. Hutmacher is a key member of the Science and Engineering Faculty, School or Mechanical Medical & Process Engineering at Queensland University of Technology in Brisbane.

He is internationally recognised for his research in regenerative medicine, tissue engineering, advanced additive biomanufacturing and soft robotics.

His work includes the use of patient-specific 3D-printed scaffolds to repair bone and other tissue. He has won multiple international awards for his pioneering research and is director of the Australian Research Council Industrial Transformation Training Centre in Additive Biomanufacturing.

In this interview Professor Hutmacher discusses his aims, inspirations, aspirations and the research challenges ahead…

The spark

“Nature provides an outstanding blueprint for scientists, engineers and architects who seek to learn from natural structures formed through millions of years of evolution. The combination of bioinspired and biomimetic (engineered design that mimics nature) strategies from soft robotics (systems built from materials with properties similar to those of living tissues) remains largely unexplored in science, technology, engineering and mathematics (STEM) disciplines.”

Research aim

“The fundamental aim of my research is to move beyond the current technological boundaries in soft robotics by bringing together engineering, digital manufacturing, biomimetics, and soft matter.

“Soft robotics uses roboticised material that is neither rigid nor run by electric motors. Incorporating soft matter into robotics will shape future manufacturing, agriculture, packaging, aerospace, healthcare, and a wide range of future applications involving human machine interactions.”

Real-world implications

“The high-risk, high-reward research I am involved in addresses Australia’s areas of critical national need. In manufacturing, research is urgently needed into critical process advances related to the manufacturability of advanced materials and the manufacture of new and existing products.”

The challenge

“To generate a new class of soft matter materials for designing and digitally, the most critical part of soft robotics, soft actuators which can change their shape or size in response to such stimuli as heat, light, pH or chemicals.”

Teaching

“One of the key roles of my teaching and PhD supervision is to convey the importance of diversity in every dimension in my labs. As a mentor I have demonstrated this by always having a almost 50/50 gender balance in my teams, with attention also to linguistic and cultural diversity.”

Key collaborators

“My lab pioneered the concept and fundamental research of a biomimetic scaffold technology platform via additively biomanufacturing of soft network composites.

“My work has been recognised with the Ramaciotti Medal for Excellence in Biomedical Research, the Alexander von Humboldt Research Award, and I am listed by the Advanced Regenerative Manufacturing Institute in 2019 as one of the 10 scientist/bioengineers who will shape the bio-fabrication landscape.”

Key collaborations include:

- Osteopore

- University of Wollongong

- University of Texas MD Anderson Cancer Centre

- Stryker

- Princess Alexandra Hospital

- Translational Research Institute (TRI) Brisbane

- Australian Centre for Complex Integrated Surgical Solutions

- Max Kelsen

- ARC Industrial Transformation Training Centre in Additive Biomanufacturing

- BellaSeno GmbH, Germany