An Australian research team is set to transform the auto repair industry worldwide with its ground-breaking new headlight repair technology.

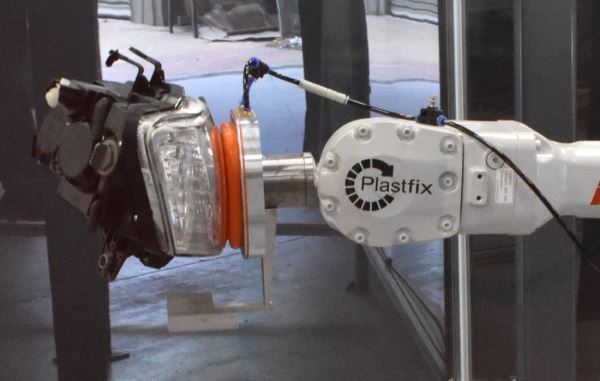

Last week, following extensive research and development, the Repair Bot team achieved a major milestone with a successful Proof of Concept demonstration of its 3D printing, scanning and robotics technology and its application in headlight bracket repair.

The team showcased the new technology at an industry event in Melbourne this week, hosted by, Professor Emad Gad, Dean of School of Engineering at Swinburne University.

Johan Noren of Swinburne University conducted a demonstration involving several key processes:

- Firstly, an existing bracket attached to a headlight was scanned, before the damaged lug was cut to the base on the headlight assembly.

- The headlight assembly (minus the lug) was then calibrated to identify the precise position for the new 3D printed stakes on which the new bracket would be attached.

- A new bracket was 3D printed on a separate printer and then positioned on the new 3D stakes, these brackets will also be inject moulded and mass produced in traditional PP material.

- And finally, the stakes are capped to secure the bracket to the lug, effectively forming a polymer rivet.

- Team Leader, Mats Isaksson was thrilled with the result.

“The team has been outstanding during this project as we overcame several significant obstacles, not the least of which was that we had to engineer our own polymer as commercial grades were unsuitable of our application.”

The Repair Bot project was launched two years ago, initially as a collaboration between Tradiebot, a leader in auto repair technology, Swinburne University and the Innovative Manufacturing CRC (IMCRC).

The team set out to repair headlight lugs using 3D printing and robotics technology.

More recently, Plastfix secured the exclusive distribution rights from Tradiebot Industries as the new patented technology solution prepares to be rolled out via the Plastfix network locally and internationally.

Guests at the industry event included AMA Group COO Dave Calder, IMCRC CEO David Chuter, WorldSkills Australia CEO Trevor Schwenke, and Plastfix CEO, Mario Dimovski.

Dr Aleksandar Markoski, Tradiebot Industries’ Head of Mechanics and Automation in the EU also attended the event.

Mr Chuter said: “It so amazing to see how far we’ve come since the idea was floated back in 2017.

“Australia is the perfect market for such innovation and this demonstration has been tremendous. Congratulations to the team at Swinburne and to all those involved throughout the journey.”

Australian innovation at its best

Mario Dimovski, CEO Plastfix also congratulated the team on a flawless demonstration and acknowledged his collaboration partners, IMCRC, AMA Group and the School of Engineering at Swinburne University.

“We’ve just demonstrated the best that Australian innovation can deliver, marrying material development, robotics and 3D printing, supported by some great ideas – we now have a robot that repairs headlights,” he said.

Looking ahead, Dimovski is confident of its commercial viability.

“The Tradiebot EU team has been working on the project for the last 12 months side-by-side with Swinburne and is preparing a more fine-tuned commercial product for today’s collision repair industry.

“There is also a secondary solution we have developed as a result of this project offering our customers repair-lugs for selected fast moving makes and models.”

Plastfix, who is a leading authority on automotive plastic repairs will be the key distributor and a major user of the new technology, initially through industry partners locally through exploring the interest in the solution from leading collision groups from around the world.