Presented last year as a prototype, igus has now developed its first isense plain bearing series with five iglidur materials for predictive maintenance.

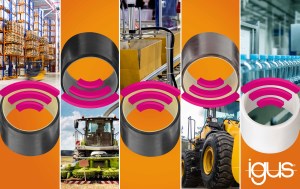

Whether in the food industry, textile machines, forklifts or construction machines, with the intelligent isense plain bearings, users receive a durable and lubrication-free solution that provides information about their wear. Maintenance can be planned in good time and machine and system failures are prevented.

Wear-resistant parts such as plain bearings must withstand extreme loads in machines and plant. If one of these bearings fails, there will be big trouble. For this reason, igus presented the first study of an intelligent plain bearing at the Hannover Messe 2019.

The aim was to develop technology integrated in the bearing to detect wear in advance and give users an early signal when the wear limit is reached.

Maintenance can be planned in advance, and unnecessary replacement and unplanned machine and system failures are avoided. After many series of tests in the 3,800 sqm in-house test laboratory, igus has now developed the first isense standard range for its lubrication-free iglidur plain bearings.

Highly stressed applications

"The catalogue range includes five materials with which we can cover a large part of highly stressed applications," says Stefan Loockmann-Rittich, Division Manager iglidur Plain Bearing Technology at igus GmbH.

“The FDA-compliant material iglidur A180, which is specifically designed for use in the food industry, the heavy-duty bearing iglidur Q2E for use in construction machinery and agricultural engineering, the all-rounder material iglidur G, the endurance runner iglidur J as well as iglidur P210 as a specialist for pivoting and rolling applications are also included.

Treotham offers all igus intelligent plain bearings in three dimensions each with an inner diameter of 20, 30 and 40 millimetres. Further sizes and materials will follow.

To connect the isense plain bearings, Treotham has four suitable igus cables with an oil-resistant and media-resistant PUR outer jacket, in four standard lengths of 1m-10m in its portfolio.

Treotham Automation Pty Ltd

1300 65 75 64