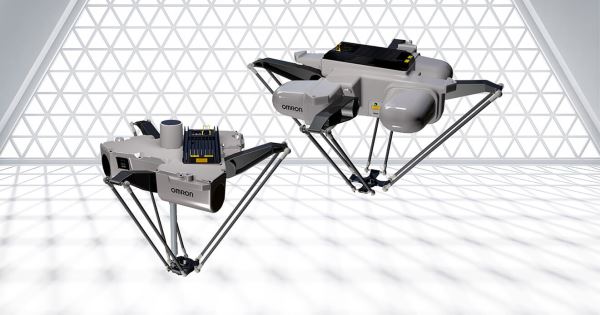

OMRON has unveiled two new parallel robots offering high payload and high-speed for faster and more flexible picking and packaging applications.

The new iX3-565 boasts a payload of 8kg, and excels at high-speed applications in packaging, food and beverage, manufacturing and pharmaceutical industries.

The powerful iX3 robot supports integrated high-speed conveyor tracking, powerful vision guidance, and easy-to-use application software created specifically for the packaging market.

It is ideal for multi-picking and for faster pick and place.

When it comes to packaging primary and secondary food, the iX3 offers the complete solution.

It features a hygienic design that minimizes contamination risks, including a standard IP65-rated work area and corrosion-resistant materials for easy wash-down. With the iX3, OMRON provides a safe solution for handling food and beverage products.

Key features include:

-

Tracks up to a conveyor speed of 1.4 m/s.

-

Designed with a high payload to support multi-hand (multi-picking).

-

Extended vertical reach allows or a 12.7 ft workspace, enabling a wider variety of packages to be used.

-

EtherCAT connectivity to the OMRON NJ501-R controller and programming through the familiar IEC 61131-3 programming language or scripting.

World first four-arm rotational platform

OMRON’s iX4 four-axis parallel robot is the company’s fastest parallel robot to date.

Boasting a payload capacity of 15kg, it is the only parallel robot in the world with our patented four-arm rotational platform delivering maximum speed, maximum acceleration and exceptional performance across the workplace.

The iX4 parallel robot offers exceptionally fast and flexible packaging and material-handling applications. OMRON’s iX4 has four arms which help evenly distribute the load on the robot and support multi-picking making it faster than all other robots.

Health and safety standards

The iX4 robot meets the sanitary standards of the US Department of Agriculture and the Food and Drug Administration for prevention of product contamination. That allows the iX4 to be accepted for meat and poultry processing.

Key features include:

-

Designed with a high payload to support multi-hand (multi-picking).

-

Meets the sanitary standards of the USDA and FDA.

-

Supports quick and high-precision pick and place applications on a fast conveyor.

-

EtherCAT connectivity to the OMRON NJ501-R controller and programming through the familiar IEC 61131-3 programming language or scripting.

Omron - 1300 766 766