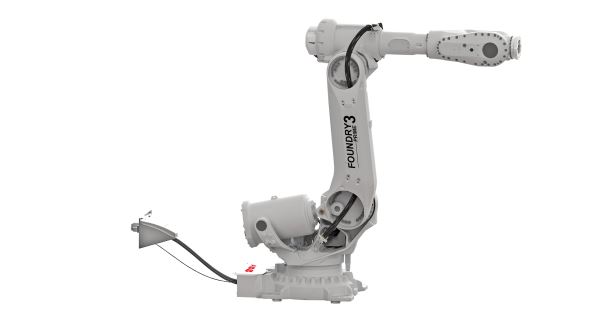

ABB has launched the third-generation Foundry Prime robot (IRB 6790), designed to withstand high-pressure waterjet cleaning applications and harsh industrial environments with 100% humidity.

The global robotics giant says the Foundry Prime robot can reduce maintenance costs by up to 60 percent.

It is IP69-rated for superior protection from water and dust and different parts can be cleaned in the same cell with zero changeover time.

“ABB’s heritage of installing robot systems in automotive factories around the world helps us understand the challenges automakers face today, and how their factories might look tomorrow,” says Vegard Nerseth, managing director of robotics for ABB.

“This helps us write the future for automation in the harshest operating environments.”

As well as increased flexibility and productivity, the ABB Foundry Prime robot delivers increased speed and an average 5 percent faster cycle time.

Easier serviceability

Its design is focused on reliability and system uptime in conjunction with optimized maintenance to enable easier serviceability.

The robot can work in an environment that is normally not suitable for industrial robots, with enhanced protection from heat, cleaning pressure, chemicals, and dirt typically found in harsh and wet environments.

The first-generation ABB Foundry Prime robot was introduced in 2005, which was painted orange, the second generation in 2007, which was painted grey, while this third-generation model is offered unpainted yet fully coated.

The robot is available in two variants – one with a 205kg payload with 2.8m reach, and one with a 235kg payload and 2.65m reach.

It is expected to be widely available by the end of the year.