Supplying power, data, fibre optics, air, water and oil to rotating applications is a major challenge for machinery designers.

Energy chains offer the most universal and modular solution, with a single system for all energy, data and media.

Now igus, a global leader in e-chains, offers these 10 valuable tips on how to optimise your rotating energy supply and equip it for a long service life. igus has experience in almost every area – from small industrial plant applications to rotary applications in machine tools, up to crane and offshore facilities with diameters of up to 32m and more. Rotation angles of over 900° have already been successfully implemented as complete turn-key systems.

1. Pay attention to correct filling of the energy chain

The rule of “one cable per compartment” is the ideal. This ensures that the cables are along the neutral axis and can move freely. The clearance around the cable should be 10% or at least 1mm. Hoses should always be laid out individually. In addition, a free space of 20% must be planned around them. Two cables per compartment are also allowable for cables with a diameter of up to 20mm. If necessary, the relative movements should be checked. Configure e-chain and interior separation online: www.igus.com.au/qc100.

2. Pay attention to the correct bend radii

To prevent kinking of cables and hoses, the minimum dynamic bend radius must be counted for. Ideally, the “Reverse Bend Radius” (RBR) should be twice the natural radius of the e-chain. Configure bend radius online: www.igus.com.au/rbr-configurator.

3. Pay attention to proper strain relief

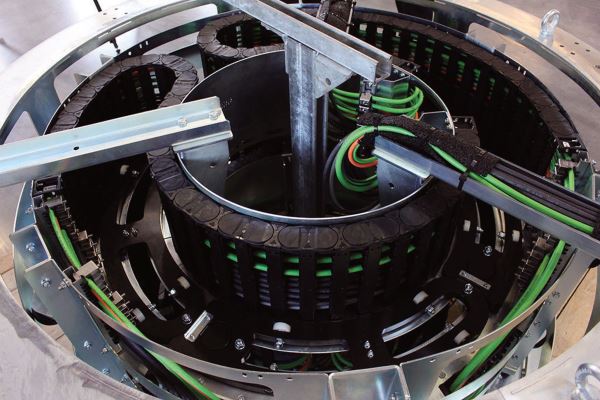

Cables that lie separately in a compartment of the energy chain should be strain relieved at both ends. Hoses and other cables are to be strain relieved at the moving end only. At the fixed end of the rotating energy supply, a cable loop should be provided in so that hoses and cables have a residual excess length as compensation for movement. In general, electrical cables should be strain-relieved with chainfix clamps in C-rails in the mounting bracket (KMA). In addition, hoses should be attached with special hose clamps.

4. Pay attention to the correct installation position

With careful planning, it is possible to reduce the displacement forces acting on the chain, thereby offering longer maintenance intervals and service life. Systems in the horizontal plane require different guide elements than vertical systems.

5. Dimensioning of the energy chain system

The length of the e-chain is calculated based on the angle of rotation and the diameters. The e-chain should be selected to be as short as possible. The chain length required for your rotation angle can be determined easily, quickly and reliably via the igus CAD configurator. Configure bend radius online: www.igus.com.au/rbr-configurator.

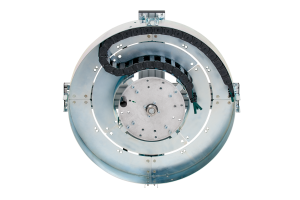

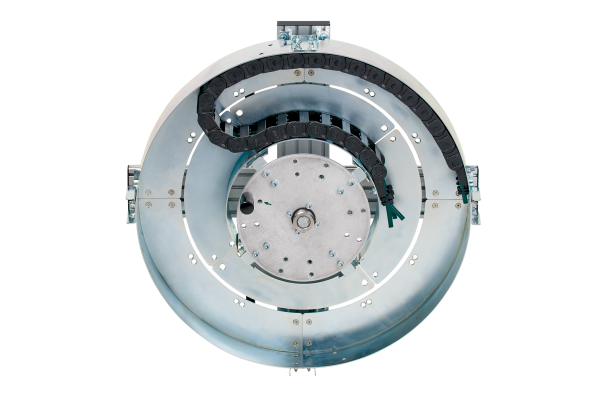

The igus standard rotary modules consist of two circular guide elements. One part of the guide trough is attached to the static part of the system and the other part to the rotating part of the system

6. Selection of the matching guide trough

Compact and slow rotating applications can be implemented inexpensively with stationary guide troughs. For larger dynamic applications, a two-part guide trough is recommended. As a result, the displacement forces are minimised and high fill weights can be easily moved.

7. Pay attention to the secure guidance of the e-chain

Additional guide plates in the guide trough prevent uncontrolled movements and the system is protected against snagging and jamming. For applications with large rotation angles and high lateral accelerations, so-called “floating islands” should be used.

8. Pay attention to external influences

In production facilities, bulk-handling or outdoor areas, rotating energy supply systems should be protected with covers or a roof if necessary. For applications with extreme dirt accumulation, consider the additional use of an open trough design to prevent dirt particles from accumulating inside the trough, which can affect the system‘s operation and life expectancy.

9. Integration of the rotating energy supply into the overall system

The right material thickness and reinforcements should be selected based on the attachment options. Care must also be taken to ensure proper and accessible layout of the cables and hoses outside of the rotating energy supply. In the case of static cables, the bend radius should also not fall below in order to ensure a long service life of the system.

10. Complete igus solutions from Treotham

Engineered and tested rotating energy supply systems complete with cables designed specifically or these applications, as well as standardised guide troughs and strain reliefs ensure maximum and guaranteed service life of the system. On request, the proven igus installation service can be provided on site by the technical engineers from Treotham.

Treotham Automation Pty Ltd

1300 65 75 64