If you think programming robots to perform complicated tasks in your warehouse is a difficult assignment – then think again.

Rethink Robotics has unveiled a new software package that should make it much easier to put robots to work – without the need for an expensive roboticist.

The new user friendly software has been designed to enable warehouse employees to program robots for various tasks – quickly and easily.

Rethink Robotics, a Boston-based firm, has built a reputation for making “easy to use” collaborative robots.

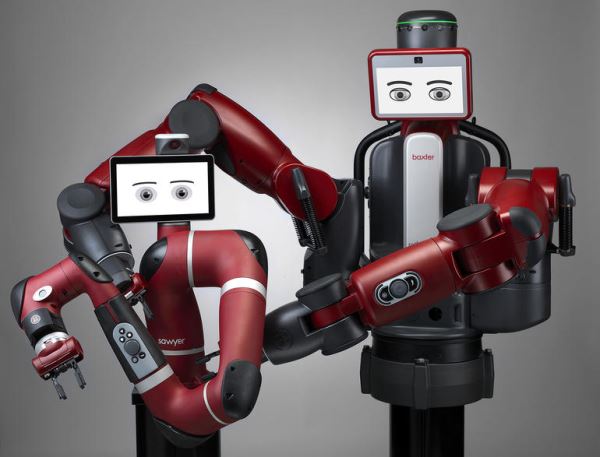

Sawyer and its predecessor Baxter are collaborative robots that can learn by demonstration.

Employees have been able to train these robots to do simple tasks, but more complicated jobs have required specialized programming.

Now, both robots will run on Intera 5, a software platform that the Rethink Robotics team says will allow manufacturers to integrate robots into factories in just a few hours.

Fast and easy deployment

Despite the obvious benefits of automation – increased productivity and reduced labour costs – the idea of adding a fleet of robots to a traditional warehouse can be overwhelming.

But now with this kind of fast and easy deployment, Rethink Robotics expects more businesses to consider the use of industrial robots in the workplace.

“With the introduction of Intera 5, we've created the world's first smart robot that can orchestrate the entire work cell, removing areas of friction and opening up new and affordable automation possibilities for manufacturers around the world,” said Rethink Robotics President and CEO Scott Eckert.

“Intera 5 is driving immediate value while helping customers work toward a smart factory, and providing a gateway to successful industrial internet of things (IIoT) for the first time.

“We wouldn't usually make such a fuss over a simple software upgrade, but Intera 5 is a complete overhaul.”

Two years in the making

IEEE Spectrum reports that the new version is based on ROS (Robot Operating System) and it is the result of 30 people working on the new code for the last two years.

The software platform has a behaviour tree that is presented as a visual diagram. Operators can still grab the robot's arm to show it what to do, but now they can also zoom in on the behaviour tree to program complex tasks based on a string of specific actions.

But if industrial robots can now be integrated in just a few hours, it will eliminate the fear they are complicated machines that require robotics expertise.

And the quick setup will help to avoid interrupting normal operations, which reduces the initial cost.

That means you can expect to see more of these user-friendly workers in factories and warehouses across the nation in coming months.