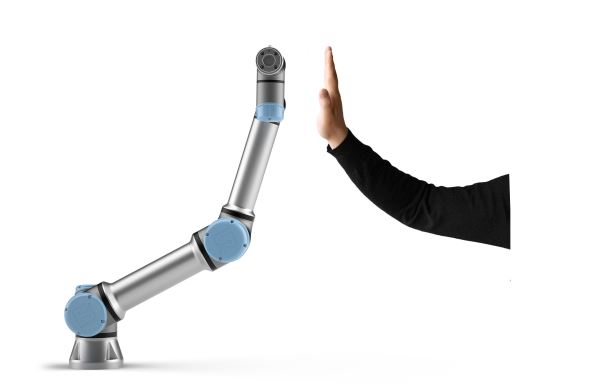

Universal Robots, a market leader in collaborative robots, has unveiled its new flagship product, the e-Series collaborative cobot.

The e-Series includes technology advances that can be used in a wide variety of industry applications. It also offers easy programming and meets the latest ISO safety standards.

Launched at Automatica in Munich, Germany last week, the company says the innovation is the result of Universal Robots “continuing to improve its ground-breaking technology”.

“Our e-Series platform is leveraging our years of experience as the market leader within collaborative robots combined with our overall product philosophy of empowering, keeping it easy and making it accessible to everyone,” said Jürgen von Hollen, president of Universal Robots.

“The technology behind e-Series as well as our unique Universal Robots+ ecosystem will give users much more operational ease and flexibility and give them greater production output.”

Unparalleled convenience

The company says the new e-Series offers a wide range of improvements in robot design and “unparalleled convenience.”

It takes just one hour to unpack, mount and program. A wrist-join-tool communication interface reduces time and complexity of integration in production line.

And all joints can be replaced in 2 to 6 minutes.

A re-designed intuitive and responsive-touch user interface simplifies programming to a few clicks on a new lightweight, wide-screen Teach Pendant. The built-in FT sensor broadens its range of applications significantly, especially those that demand greater sensitivity.

Collaborative automation is made easier with 17 safety functions.

The e-Series is certified by TÜV Nord, and all these functions are in compliance with the EN ISO 13849-1 and EN ISO 10218-1 (Cat. 3 PLd) machinery safety standards for unobstructed human-robot collaboration.

Universal Robots says it will start taking orders for the e-Series immediately and plans to begin shipping units to customers from August this year.