Robots are big business.

By 2020, global marketing consultancy IDC predicts the industry will more than double to $A248 billion.

But there's still a lot that today's models can't do, partly because they are mostly made of rigid metal or plastic.

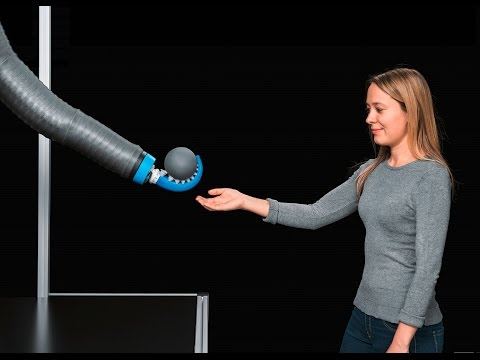

Robotics researchers are now focusing on softer, lighter robots that are less reliant on external power. These future robots could interact more safely and predictably with humans, go where humans can't, and do some of the robotic jobs that other robots still can't manage.

The new soft generation robots now have arms that curl and grip like an octopus. Others wriggle their way inside an aeroplane engine or forage underwater to create their own energy.

This is technology that challenges how we think of, and interact with, the robots of the not-too-distant future.

Move away from traditional robots

A recent academic conference in Singapore showcased the latest advances in soft robotics, highlighting how far they are moving away from what we see as traditional robots.

"The theme here," says Nikolaus Correll of Colorado University, "is a departure from gears, joints and links."

One robot on display was made of origami paper. Another resembled a rolling colostomy bag. They are more likely to move via muscles that expand and contract through heat or hydraulics than by electricity.

Some combine sensing and movement into the same component – just as our fingertips react to touch without needing our brain to make a decision.

These ideas are already escaping from the lab.

Snake-lie robot

Rolls-Royce, for example, is testing a snake-like robot that can worm its way inside an aircraft engine mounted on the wing, saving the days it can take to remove the engine, inspect it and put it back.

Of all the technologies Rolls-Royce is exploring to solve this bottleneck, "this is the killer one," says Oliver Walker-Jones, head of communications.

The snake, says its creator, Arnau Garriga Casanovas, is made largely of pressurised silicone chambers, allowing the controller to propel and bend it through the engine with bursts of air. Using soft materials, he says, means it can be small and agile.

For now, much of the commercial action for softer robots is in logistics, replacing production-line jobs that can't yet be handled by hard robots.

Overcoming uncertainty

The challenge, says Cambridge Consultants' Nathan Wrench, is to overcome the uncertainty when handling something – which humans deal with unconsciously.

This includes figuring out its shape and location and how hard to grip it, and distinguishing one object from another.

"This is an area robots traditionally can't do, but where (soft robots) are on the cusp of being able to," said Mr Wrench.

Some hope to ditch the idea that robots need hands. German automation company Festo and China's Beihang University have built a prototype OctopusGripper, which has a pneumatic tentacle made of silicone that gently wraps itself around an object, while air is pumped in or out of suction cups to grasp it.

Monitoring water salinity

The ocean has inspired other robots, too.

A soft robot fish from China's Zhejiang University swims by ditching the usual rigid motors and propellers for an artificial muscle which flexes. It's lifelike enough, says creator Tiefeng Li, to fool other fish into embracing it as one of their own, and is being tested to explore or monitor water salinity.

And Bristol University in the UK is working on underwater robots that generate electrical energy by foraging for biomatter to feed a chain of microbial fuel-cell stomachs.

Soft robots are also being developed to decontaminate polluted waterways and monitor industrial infrastructure.

Source: Sky News