ANCA’s new smart factory Management Suite uses virtual machine monitoring technology to achieve premium grinding efficiencies – in or out of the office.

Users can now monitor the performance of their machines no matter where they are in the world. The new software also enables companies to run smart factories by providing live production information to make data based decisions on operational improvements.

Thomson Mathew, ANCA Software Product Manager said: “We listened to what our customers needed to improve their grinding performance.

“They told us they wanted a smart factory concept where machines are grinding tools all day everyday with minimal intervention and the ability to remotely monitor machines for better intelligence on grinding performance and down-times.”

The technology is ideal for companies planning to use CNC grinding machines for a long tool batch during the weekend.

A team member can now monitor production, keeping an eye on their phone or other device from home and is immediately notified if there is a machine down.

Lost productivity

“In the past, this person would have had to be on site all weekend,” said Mr Mathew.

“This is a cost to the business – or would have resulted in lost productivity as the problem would only have been picked up when people returned on Monday to find the grinding had stopped at midday on Saturday.”

Mr Mathew says data analytics is the key to improving business processes.

“Our new software suite has been designed to give our customers as much intelligence as possible on their machines performance in a simple to use interface.

“Gone are the days where customers rely on manual records of machine performance with software that provides factual reports and analytics to enable informed decisions.”

The machine analytics provided by the Management Suite gives companies the ability to produce highly accurate reports on machine usage allowing them to identify waste and increase overall equipment efficiency.

The Management Suite dashboard provides users with the flexibility to monitor the production of their machines in and out of the office – all they need is to be connected to their server via the internet. It can be viewed by multiple people in the company to ensure a connected team who can work together remotely and onsite to maximise their operational efficiencies.

“The new software means that our customers can decide where their time will be best spent; meeting with clients, visiting other sites or even having lunch out of the office in the knowledge that their machines are operating at a premium,” said Mr Mathew.

Features and benefits

- Monitors machine and production in real time and delivers up to date information, greatly enhancing visibility and control in manufacturing operations.

- Reduces costly machine down-time by immediately notifying when a machine has ceased production, with reasons for the stoppage via an email or SMS to the relevant personnel.

- Provides complete visibility of the machine status and activity from the office PC or from anywhere in the world if the user is logged into the company’s server.

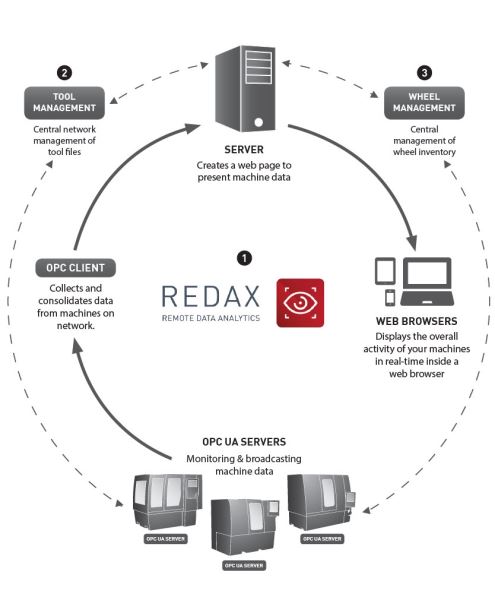

The Management Suite comprises of three products – Tool Management, Wheel Management and RedaX.

- Tool Management maintains revision control of your grinding programs allowing you to easily revert to older versions. You can also visually identify program changes using the file difference tool.

- The Wheel Management product is a central inventory for wheels and wheel packs. It provides a platform to easily share wheel packs and qualification data between machines. It also has a handy search function so that operators can easily find what they are looking for.

- The RedaX product is a remote data analytics real time monitoring solution for machines. Its open platform communication unified architecture is part of RedaX and runs on machines to monitor and broadcast machine data. From this users can consolidate the findings on a web page that is displayed in a real-time web browser.