Konica Minolta, a leading supplier of 3D printing equipment and services in Australia, is working with partners and customers to help address the likely shortage of personal protective equipment (PPE) and ventilators required on the frontlines of the fight against COVID-19.

Matt Hunter, innovation product manager, Konica Minolta, says other countries are now facing rapidly-dwindling supplies of PPE and lifesaving ventilators as they battle the virus.

“3D printing offers a unique opportunity to address these shortages by providing a fast, reliable production method that means essential equipment can be manufactured and delivered to hospitals without long lead times,” he said.

Mr Hunter said Konica Minolta has reached out to key customers and partners in the 3D printing space, as well as health authorities across Australia, to find solutions.

“As a result, Konica Minolta is facilitating the development and manufacture of two key pieces of equipment: the hard-to-source Venturi ventilator valve for patients – and the essential P2/N95 filters for PPE for frontline health workers.”

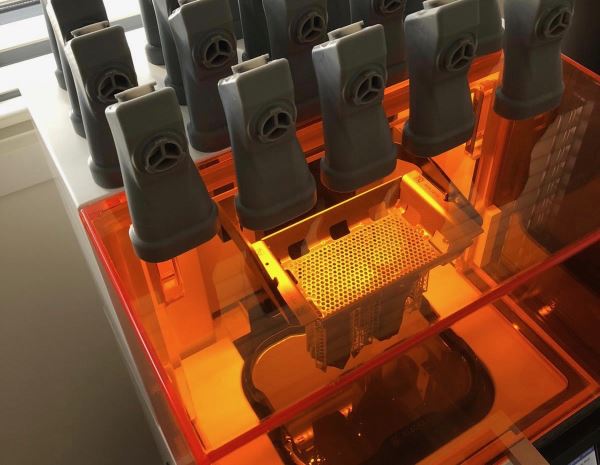

Konica Minolta partner 3D Systems has designed the Venturi ventilator valve for 3D printing and sent the file to Konica Minolta, which will print the valves if they become required.

The 3D-printed valve uses biocompatible, sterilisable, high-temperature-resistant material, making it ideal for medical use. And, because it’s 3D printed, the team can provide high volumes at unprecedented speeds, potentially meeting demand as the COVID-19 crisis hits its peak.

Cost-effective masks

The P2/N95 filter is an essential part of the PPE that healthcare workers require. It filters the virus out of the air being breathed so the wearer breathes clean air. These cost-effective masks with a 3D-printed adaptor and easily replaceable filtration can be mass-produced and sent immediately to healthcare workers on the frontline.

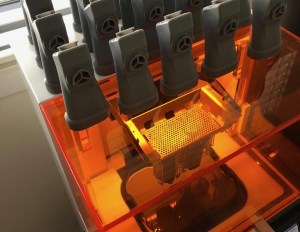

Konica Minolta worked with Erebus Motorsport to develop the filter, which is printed using a 3D Systems Figure 4 3D printer. An existing Konica Minolta customer, Erebus had already been in contact to see how 3D printing could help in the fight against COVID-19. Working with Supercars medical delegate, Dr Carl Le, the team created the e-Mask, a snorkel-like face mask with a 3D-printed adaptor for the easy replacement of P2/N95 filters.

The Erebus team and Dr Carl Le also designed a ventilated Perspex box, which is placed around the patient’s head and chest to provide a continuous filtered airflow, called the e-Aerosol Box. The e-Aerosol Box has already been distributed to hospitals around Australia, as the Erebus team now looks at adapting the model for ambulance transportation.

Fast response required to save lives

Mr Hunter says at this stage, the demand for PPE is unknown, as Australia works to flatten the curve.

“However, it’s likely that a fast response will be required to save lives,” he says.

“By facilitating the capacity to 3D print these lifesaving components, Konica Minolta and our customers and partners are playing a small but important role in the fight against COVID-19.

“Having thoroughly tested the parts, we know they work.”

Mr Hunter says Konica Minolta is now looking for input from other customers and partners to increase capacity further and potentially find new ways to contribute.