As the world battles to contain the deadly COVID-19 pandemic, protecting medical staff against infection has become a main priority.

Stocks of personal protective equipment (PPE) are rapidly depleting across hospitals and medical facilities globally.

Now, 3D printing is being used to help combat equipment shortages.

In Italy, engineers addressed severe ventilator shortages by making ventilators using 3D-printed parts.

The technology is ideally suited to solving immediate and urgent challenges because of its ability to quickly develop prototype models leading to better end products.

Also, 3D printing is fast and affordable, so PPE items can be produced quickly and delivered to healthcare facilities in need.

Designers can use different designs and materials, to help lower costs and improve the efficacy of the final product.

Y Soft, a Czech Republic specialising in 3D printing technology, has now turned its attention to finding to finding solutions to PPE shortages in hospitals.

Using face shields as an alternative to masks

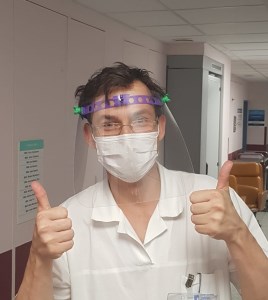

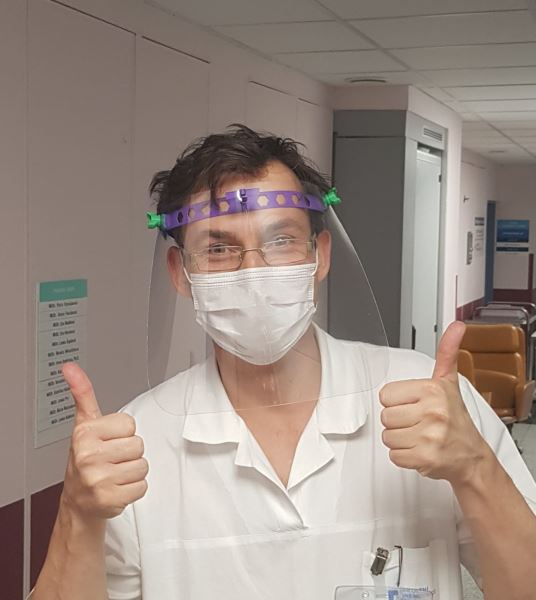

Adapting a previous design, the team has created 3D printed plastic face shields to protect frontline medical staff.

The shields are being used throughout hospitals in the Czech Republic, including the COVID-19 collection tent of the Central Military Hospital, Polyclinic Vinicní in Brno, Bohnice Hospital psychiatric hospital in Prague, and Thomayer Hospital, one of the largest medical facilities in the country, also in Prague.

The shield uses a sheet of plastic that sits just off the wearer’s face, which is inserted into a 3D printed frame and is secured around the head with a rubber band. These plastic sheets can be removed and disposed of so, instead of having to discard the whole piece of equipment, the 3D-printed head frame can be sanitised and reused.

The shields can be used by medical staff when the more common N95-type face masks are not available or when staff are not in direct contact with patients, such as in laboratories and other areas of medical facilities. The shields can also be used in addition to the N95s for added protection.

Plan to ramp up production

Using YSoft be3D eDee printers in the Czech offices, the Y Soft team plans to increase production capacity to 500 shields per day, while also adapting the shield design to incorporate feedback from hospital staff.

Other Y Soft offices around the world are exploring opportunities to replicate the shields and provide them to healthcare facilities in other regions.

The company has been focussing on building up the supply chain in Europe, with plans to deliver more than 9,000 face shields already requested.

It is also exploring ways to roll out the program or something similar to other countries, including Australia.

Instructions and design files for the face shields can be downloaded at be3dacademy.com for general use.

“The world was not prepared for the current situation,” says Václav Muchna, founder, Y Soft.

“While we cannot handle massive production, it turns out that everyone can voluntarily contribute their own efforts.

“That's why we got involved as a company. Our office workers around the world can also use affordable 3D printers to print protective equipment for healthcare professionals. It is a way to help people in hospitals. We are in this together.”